About us

TOP 20 largest molybdenum producers in the world

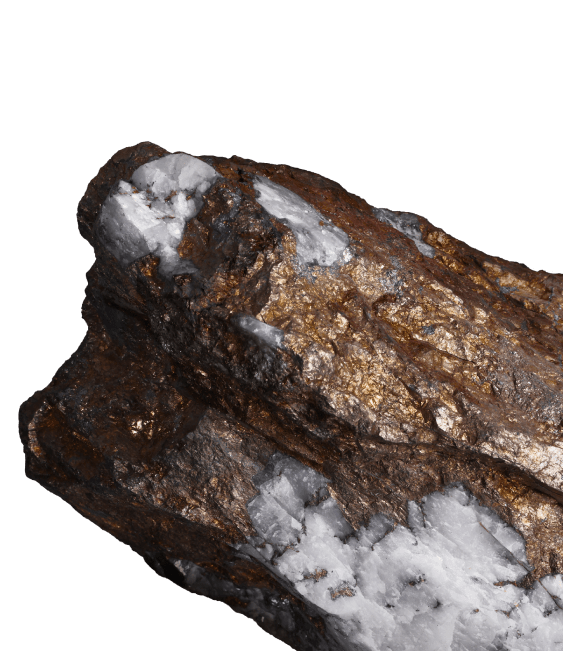

"Zangezur Copper Molybdenum Combine" CJSC is located in the south of the Republic of Armenia, in the city of Kajaran, Syunik Province, operating the largest mining project in the region with proven significant reserves of molybdenum and copper.

ZCMC’s share of global molybdenum production

Of the world’s reserves of molybdenum are located in the Syunik region

Molybdenum reserves at the Kajaran deposit

Location

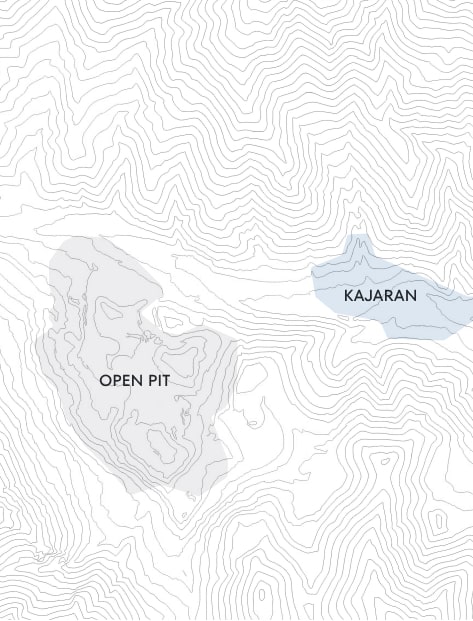

The Kajaran mine is located on one of the spurs of the Zangezur ridge, in the valley of the Voghji River. The relief is rugged, with absolute elevations of 1800-3900 meters. The quarry is located 1.7-2.5 km southwest of the city of Kajaran, at an altitude of about 2200 m above sea level.

The area has high elevation, with mountains up to 4000 m high in the immediate vicinity of the open pit. The processing plant is located near the Kajaran mine approximately 27 km away from the Artsvanik tailings dump in a straight line.

History

Our history

ZCMC, and the Kajaran deposit, has a long standing history with an important role in the development of the country and the region.

initial geological prospecting

The deposit has a long standing history. Large scale geological research was carried out since the 1880s.

Being located at a considerable distance from the communication routes of the time, the mine was initially exploited irregularly. The history of the formation and uninterrupted operation of the project is closely connected with the establishment of Soviet rule in Armenia, when mining enterprises and metallurgical plants were nationalized.

major undertaking

report for the Kajaran mine

construction of the combine

open-pit operation

shutdown and recommissioning

As a result of the economic crisis after the collapse of the Soviet Union in 1991, the operation of the combine was halted. It was recommissioned in 1994.

PRIVATIZATION OF THE COMBINE

In December 2004, the Zangezur Copper Molybdenum Combine was privatized. The controlling stake was acquired by the German group “Cronimet Mining”.

NEW SHAREHOLDERS

Activity

We create a shared future by developing responsible production

MoreWe mine and process ore, produce copper and molybdenum concentrates. Those metals are essential resources for producing thousands of everyday products used for the needs of the global community and for improving the living standards.

The metals we produce are critical for the economic growth and decarbonization, and we are committed to producing them in a safe, responsible and efficient manner.

Production stages

Mining - extraction and transportation of copper-molybdenum ore.

Ore crushing and transportation – primary crushing is performed here.

Processing plant - enrichment (flotation) is carried out: crushing and enrichment of ore, dehydration and drying of copper and molybdenum concentrates, obtaining the final product.

Tailings dam - an engineered structure designed to store mining and ore processing residues.